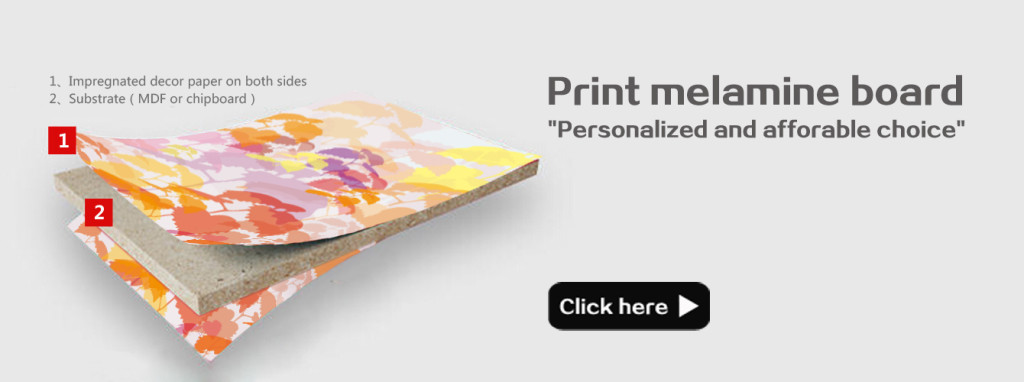

Digital melamine faced board

By heat bonding impregnated paper under high pressure to substrate(which are MDF and chipboard normally),we’ve developed custom print melamine board.Flat surface,anti-shock and solid internal structure turns itself into the most used construction board with cost-effective feature.

It shares wide range of applications from kitchen to office furniture.Now, with digital print decor paper, our melamine board are ready to provide inspiring ideas everywhere,anytime.

Thickness(mm)

4-25

Size(mm)

1220*2440/1830*2440/2100*2500/2070*2500

Material

overlay paper/digital print decor paper/backer sheet/substrate

Surface treatment

Matte/Satin/Embossing/high gloss

Melamine sheet is also named thermally fused laminate due to its thermosetting lamination process.

1. Digital print decorative paper

send us design patterns for printing on decor paper. Know more printed decor paper.

2. Substrate (MDF/chipboard)and paper preparation

Besides custom print paper, overlay paper and susbtrate from 4mm to 30mm are required.please ensure surface clean

and flat before lamination and sometimes a melamine backer sheet is needed to balance the panel.

3. Melamine boards lamination

Applying melamine decor paper on MDF/chipboard by thermosetting in 135-150 Celsius degree with backer sheet on back

4. Finishing

Use CNC machine to finish edge and corner flat and edge banding whole board.Special surface treatment could be request.

Why choose digital print melamine board?

· High resolution patterns with defects dots eliminated down to 2 mm²/m²

· Outstanding color fastness under strong light and being UV rays absoprtion

· Excellent anti-abrasion ,suitable for high traffic location

· being cost-effective,covering various budget options and wide application for most family using

· high quality substrates to meet E0 formaldehyde emission standard,down to zero harmful gas emission

· High impact resistance makes itself extremely solid internal structure

· Easy-to-shape character allows creative ideas to be acheived at afforable price

1)What are MDF and its features?

Medium-density fiberboard (MDF) is an engineered wood product made by wood fibers, often in a defibrillator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure.

Compared with chipboard, a tinier wood fiber provides MDF a more solid and stable internal bond with consistent strength.Besides, it could be customized into any shape with flat surface and smooth edges,which meets some special decoration requirement,of which the typical is curved surfaces.

As to its drawbacks,a low grade MDF may swell and break when saturated with water/humid environment,having a worse screw-holding performance ,and the most serious problem,of course, leads to its unqualified formaldehyde emission.

2)What are chipboard and its features?

Chipboard, also known as particleboard, is an engineered wood product manufactured from wood chips, sawmill shavings, or even sawdust, and a synthetic resin or other suitable binder.

Compared with MDF,the irregular internal composition provides a strong horizontal load bearing and better insulation character.Similar as MDF,various surface layes,such as veneers and HPL could be laminated onto flatly.Besides,less resins is used in processing,which is cost-effective and healthier to human.

In terms of its disadvantages,the irregular composistions makes milling process harder and it’s prone to deform and discolored,particularly when it’s not covered with paint and another sealer.

3)What is the best way to store melamine board?

Like any other wood product, particleboard and medium density fibreboard (MDF) expand and contract as they pick up or lose moisture. Board products must be stored in dry conditions which are approximately the same conditions as its final use.

4)What are edge treatment of melamine board?

Both PVC and Melamine edging are designed to edge melamine panels. For a sturdier, tough edging PVC is often used. It is widely used for corners and edges that are exposed to being knocked and damaged. Melamine edging is made out of impregnated melamine edge tape and can be applied straight to curved edges.

5)How to clean and maintain melamine face board?

Clean with a clean cloth and warm water and normal domestic cleaners or dish soap. It must be noted that the domestic cleaners should have no abrasive ingredients.

6)What are common thickness of melamine board ?

MDF booard

Common thickness

3mm/9mm/12mm/15mm/16mm/18mm/20mm

Common size

2440mm*1220mm

2440mm*1830mm

2500mm*2100mm

Particle board

Common thickness

8mm/12mm/16mm/19mm/25mm/30mm

Common size

1220*2440mm

1525*2440mm

1830*2440mm

1830*2745mm

Get interested ?